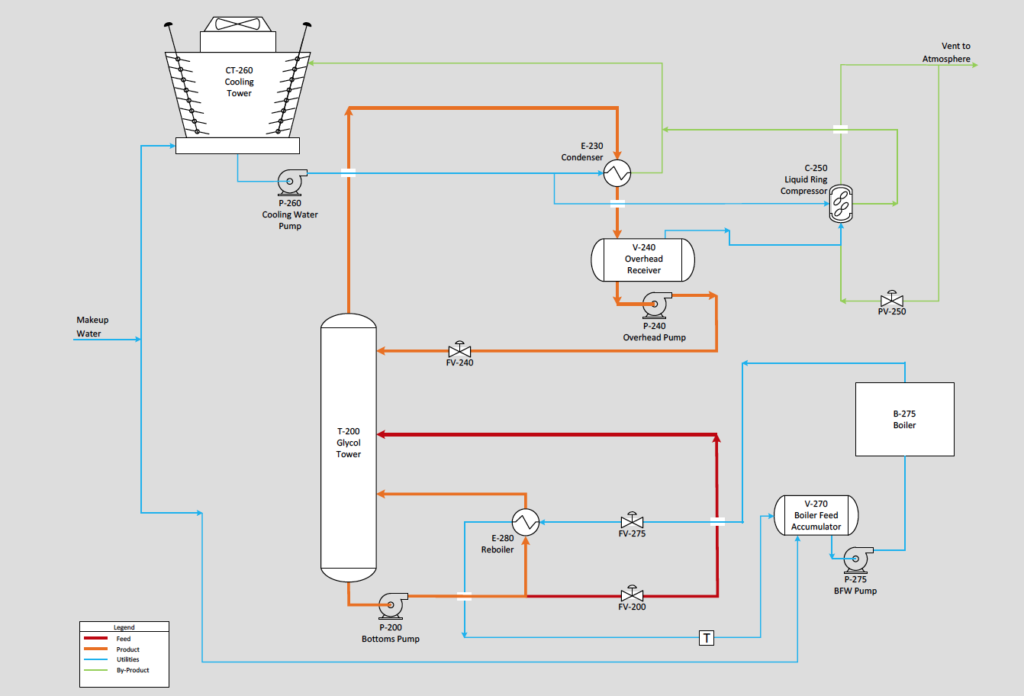

The trainer is 60′ L x 12′ W 22″ H and built from welded, structural steel. It sits on an industrial grating work surface, and the process piping is welded and flanged. This hands-on trainer unit includes:

The HOT MODEL 3 comes with its own instrumentation:

Training curriculum accompanies each HOT MODEL filled with exercises and procedures. This includes an operating manual which details operating procedures for startup, shutdown, emergencies, and exercises you can run students through on your hands-on trainer unit.

Dynamic Process Simulation is available for the HOT MODEL 3, which encompass:

You can also extend the curriculum to supplement the standard learning objectives provided with the hands-on trainer unit. This includes process equipment animations that detail the inner workings of equipment and have drag-and-drop exercises along with quizzes. You may purchase these as an additional package, or you may purchase each piece a la carte with your Glycol Distillation Trainer.

Systran is proud to provide these units to schools and companies across the United States through our partnership with Polaris. Each unit gives students the opportunity to gain real-world, hands-on experience in a safe learning environment; future operators get the chance to work on full-size industrial equipment with true-to-life instrumentation and DCS. In addition to these benefits, the curriculum and training aids are fully developed so that you can give all your attention to teaching rather than drafting complicated lesson plans.

Through Systran’s partnership with Polaris, we work together with Simtronics to create simulations for the HOT MODELs. Simtronics focuses on hands-on trainer specific simulations and training aides while we here at Systran focus on animations, workbooks, and augmented reality simulations for the HOT units.

Together, we provide dedicated training, service, and support located right here in Houston, Texas.

The only things you will need to supply for your new hands-on trainer unit are:

Systran currently offers 3 different Polaris Hands On Trainer (HOT) units for purchase: Fundamentals, Glycol Distillation, and Liquified Natural Gas (LNG)

Yes! Each unit comes with operating manuals, procedures, and exercises to help teach students in a controlled industrial environment.

They will learn startup/shutdown/emergency procedures, equipment/process troubleshooting, effective rounds, shift handover, equipment lineups, and energy isolation (through lockout tagout) of equipment and systems.

Yes! We can provide Simtronics dynamic process simulations with workbooks, a 3D virtual field operator, and Systran’s process equipment animations.

Visit the Polaris website for more information!

| Cookie | Duration | Description |

|---|---|---|

| cookielawinfo-checkbox-analytics | 11 months | This cookie is set by GDPR Cookie Consent plugin. The cookie is used to store the user consent for the cookies in the category "Analytics". |

| cookielawinfo-checkbox-functional | 11 months | The cookie is set by GDPR cookie consent to record the user consent for the cookies in the category "Functional". |

| cookielawinfo-checkbox-necessary | 11 months | This cookie is set by GDPR Cookie Consent plugin. The cookies is used to store the user consent for the cookies in the category "Necessary". |

| cookielawinfo-checkbox-others | 11 months | This cookie is set by GDPR Cookie Consent plugin. The cookie is used to store the user consent for the cookies in the category "Other. |

| cookielawinfo-checkbox-performance | 11 months | This cookie is set by GDPR Cookie Consent plugin. The cookie is used to store the user consent for the cookies in the category "Performance". |

| viewed_cookie_policy | 11 months | The cookie is set by the GDPR Cookie Consent plugin and is used to store whether or not user has consented to the use of cookies. It does not store any personal data. |