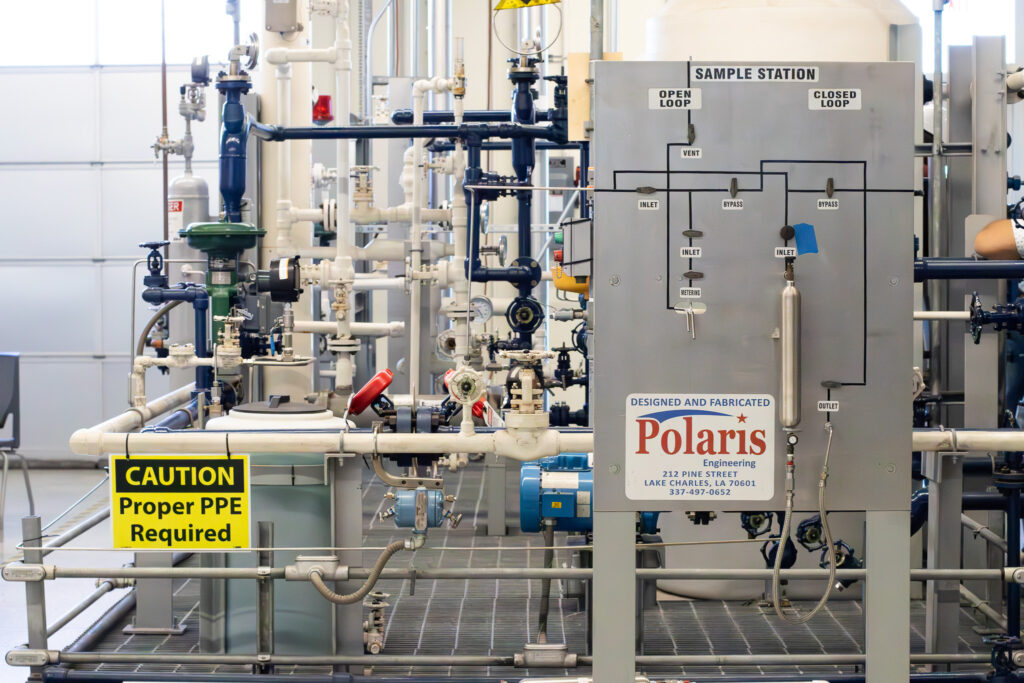

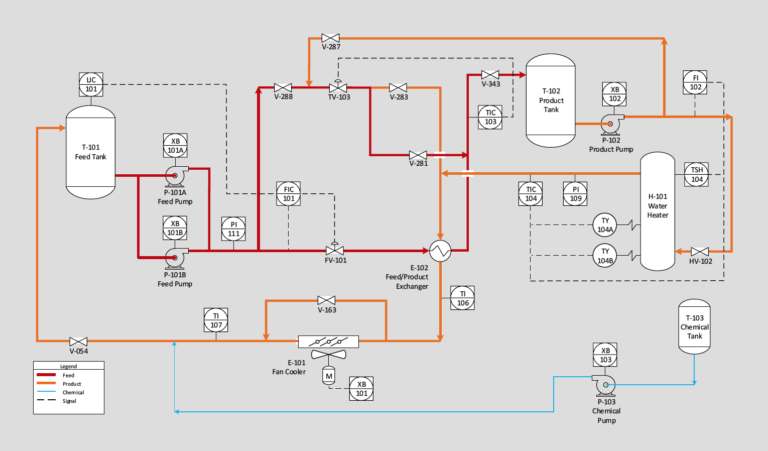

The Polaris HOT Unit 1, also known as the Operations Fundamentals Trainer, is a hands-on training unit designed to teach the fundamentals of process operations in a safe and realistic manner. It provides learners with practical experience with industrial equipment and instrumentation, allowing them to develop real-world skills in a controlled environment. The unit includes a comprehensive training program with detailed operating manuals and is designed to meet industry engineering standards and regulatory requirements.

This unit is equipped with a comprehensive range of industrial-grade equipment, designed to simulate real-world process operations. The following components work together to provide a hands-on learning experience, allowing learners to explore and understand the intricacies of process systems. Key equipment includes:

The trainer is 24′ L x 10′ W 7′ 6″ H and built from welded, structural steel. It sits on an industrial grating work surface, and the process piping is welded and flanged.

Site requirements:

Training curriculum accompanies the HOT Model 1 and is filled with over 100 exercises, scenarios, and procedures. This includes an operating manual which details all operating procedures of startup, shutdown, emergencies, and exercises.

The Polaris Hot 1 AI is an AI-powered teaching assistant built for the HOT Unit Model 1. Save time, teach more effectively, and support student success. Whether you’re in the classroom, lab, or building out curriculum.

From lesson planning to lab design, the Polaris Hot 1 AI gives you fast, reliable support that keeps your training aligned with industry standards.

• Plan smarter with built-in lessons

• Simplify teaching with clear explanations

• Train hands-on with ready-to-use materials

• Get answers on HOT1 components and procedures instantly

To further enhance the learning experience and provide a complete training solution, we offer a range of optional training aids that can be integrated with the HOT Unit 3. Available training aids include:

Process Equipment Microlearning: A library of interactive and immersive modules for learners to explore a wide range of process equipment

Process Technology for zSpace: A 3D augmented reality platform that enables interactive and immersive learning experiences

LOTO EXP: A lockout/tagout training simulation that teaches learners critical safety procedures in a safe and controlled environment

Simulator-based curriculum includes CPM–300 Process Model, Training Workbook, Virtual Field Operator, Virtual Training Environment, and E–Learning.

| Cookie | Duration | Description |

|---|---|---|

| cookielawinfo-checkbox-analytics | 11 months | This cookie is set by GDPR Cookie Consent plugin. The cookie is used to store the user consent for the cookies in the category "Analytics". |

| cookielawinfo-checkbox-functional | 11 months | The cookie is set by GDPR cookie consent to record the user consent for the cookies in the category "Functional". |

| cookielawinfo-checkbox-necessary | 11 months | This cookie is set by GDPR Cookie Consent plugin. The cookies is used to store the user consent for the cookies in the category "Necessary". |

| cookielawinfo-checkbox-others | 11 months | This cookie is set by GDPR Cookie Consent plugin. The cookie is used to store the user consent for the cookies in the category "Other. |

| cookielawinfo-checkbox-performance | 11 months | This cookie is set by GDPR Cookie Consent plugin. The cookie is used to store the user consent for the cookies in the category "Performance". |

| viewed_cookie_policy | 11 months | The cookie is set by the GDPR Cookie Consent plugin and is used to store whether or not user has consented to the use of cookies. It does not store any personal data. |